Choosing the Right Blade Matters

Words: Bryant Figueroa

Words: Bryant Figueroa, Marketing & Creative Director, iQ Power Tools

Photos: MASONRY Magazine, iQ Power Tools

The primary purpose of a saw is that it can cut quickly and efficiently. Clearly, the most critical component of cutting is the blade. If the blade isn’t of good quality, then you will have a bad experience. This will include poor cuts and excessive load on your saw motor, which ultimately leads to overheating and overall damage.

No matter if you are a mason, hard-scaper or concrete contractor, there are four main categories that a contractor should completely understand about selecting the right diamond saw blades. These four categories are diamond pattern, tension, bonding and maintenance. Understanding the basics of diamond saw blades will help you choose the best option for each of your jobs... and get every job done faster.

BLADE TESTING

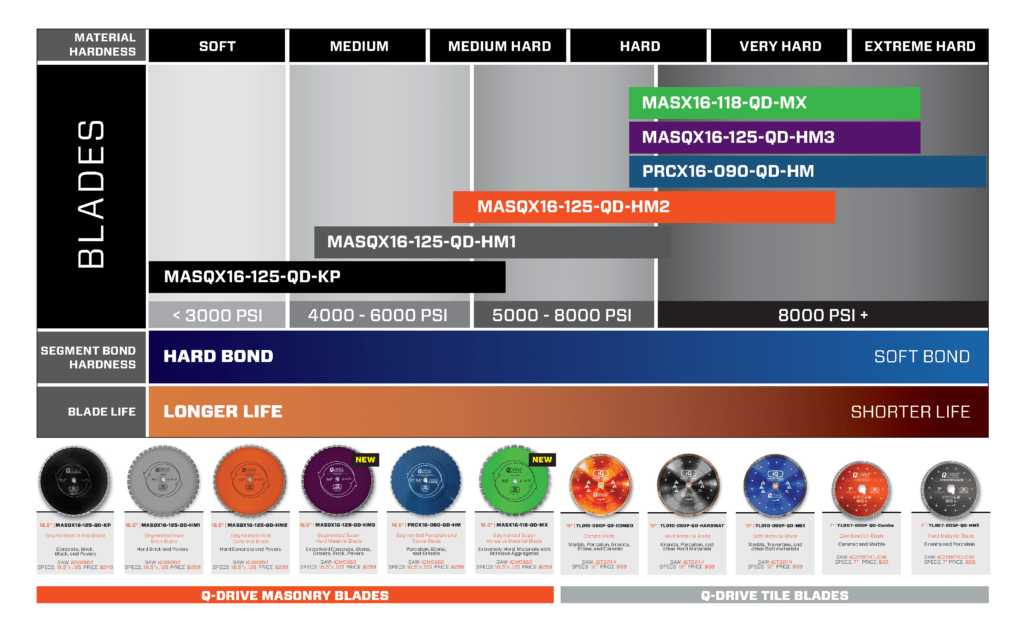

Finding the perfect match between the saw, the blade and the material is crucial. Blade choice is important as it affects the machine and potentially can ruin its motor if the wrong blade is used. Additionally, PSI (pound per square inch), which is the hardness level of materials, is also an important factor to consider.

Knowing the hardness of the aggregates in materials to be cut helps in selecting a blade best suited for the job. Furthermore, it's essential to recognize that different regions around North America have varying aggregates in their materials; just because the label says "concrete diamond blade" doesn't necessarily mean it's the best option for the material to be cut. Knowing the material variations and PSI levels can help select the right blade for the material and ultimately improve efficiency.

DIAMOND PATTERNS: ARRAYED VS RANDOM

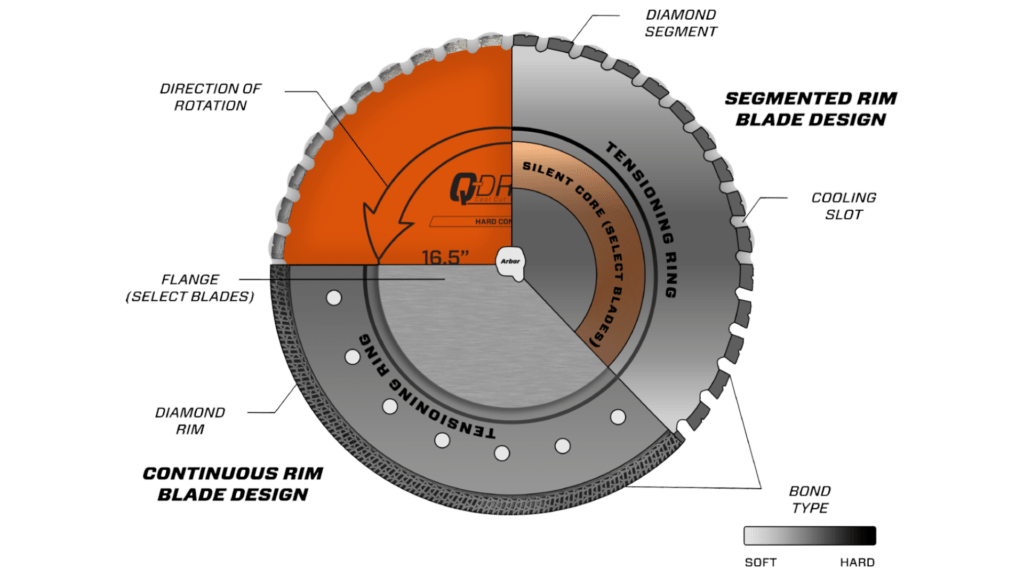

Diamond blades use diamond crystals mixed into the blade segment to maximize precision cutting through the material. The pattern of those diamonds determines the rate at which they will grind. The segment or tip of the blade is made up of a metal matrix with small diamonds placed randomly or arrayed within this metal matrix. This metal matrix is designed to cut a specific type of material and wear away at just the right rate to expose fresh diamonds that are cutting the material.

TENSION

Blade tension is a vital aspect to consider. If not monitored correctly, users can lose the blade prematurely by forcing a blade through the material faster than it would naturally cut it. Most saw manufacturers will typically set the blade tension, but it is imperative to continuously monitor for signs of under/over tensioning while the blade is in use. Hairline cracks, not cutting straight enough, blade breakage are all signs for you to be on the lookout.

HARD VERSUS SOFT BOND

The bond (or metal matrix of a diamond saw blade) is the glue that holds the diamonds in place. It is a mixture of three or more different metal powders pressed together at an extremely high temperature. The hardness of the bond determines what the blade should be used for and also, its lifespan. Generally speaking, a soft bond blade is used to cut hard material, whereas a hard bond blade should be selected to cut softer material.

BLADE MAINTENANCE

HOW TO CONDITION YOUR BLADE

When cutting with a new blade, make 25 or more cuts through scrap materials like standard medium-hard ceramic or medium-hard concrete to open up the diamond matrix. This will optimize the blade for future cutting quality and performance.

MAKE SURE TO TEST YOUR BLADE

Not sure of the PSI of your material? Not sure if the glazing will chip? Then test it. Make some test cuts and then see which blade cuts that material the cleanest, before you start a project. Work smarter and plan ahead.

DRESSING THE BLADE

Dressing the diamond blade is essential to maintaining its life. After a large number of cuts (or when switching from different materials) dressing the blade will remove build-up on the segments and expose fresh diamonds. This allows your blade to cut sharper and faster without putting pressure on the saw motor.

Sometimes your blade may stop cutting... even though you have noticeable segment left. In this situation, the cutting layer of diamonds has been stripped away leaving only metal matrix, which will not cut by itself. What most people don’t realize is if there is still segment on the blade, then fresh diamonds can be exposed by using a dressing stone or some abrasive material to wear the metal matrix back and expose the fresh diamonds, 9 times out of 10. This definitely can extend the life of a diamond blade.

Mason contractors are in a challenging business environment. One which is evolving with innovative products and materials on a daily basis. Taking the time to learn everything you can about these new products, and how to care for them, makes good business sense. In today’s work environment, you need every advantage possible to complete projects efficiently, safely, on time and on budget.